Pete is well known for his precision designs and flawless finishes. These areas of expertise will be the focus of his demonstrations in St. Louis. Pete will show attendees his precision jig for ring centering and alignment. In another rotation, Pete will share the multistep process he uses for accomplishing the high quality finish he achieves on all his pieces.

Originally from Brooklyn NY, currently living in Calera Alabama about 25 miles south of Birmingham.

Retired from the automotive manufacturing industry.

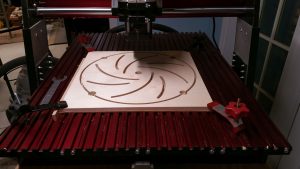

I have been a wood turner for over 25 years and became a segmented enthusiast about ten years ago. This includes standard segmented pieces as well as open segmenting and twister style pieces. My current workload consists of a 50/50 split of traditional turnings and segmented.

I am currently branching out to teaching both styles of turning. I find it invigorating sharing the joy of turning wood.

I am particularly proud of the finish on my pieces and spend the extra time and effort to achieve a high gloss finish. The finishes that I typically use are spray on lacquer, MinWax wipe on poly and General Finishes WoodTurners Finish (water based poly). The technique is the same for all of them.

Here are some steps that I use in finishing my pieces.