I was just really getting involved in segmenting about 6-8 months before the Symposium that was held in Boston in 2016. I was really getting to enjoy it. But, then at the Symposium, I fell in love with open segment, and all was lost.

I had built myself a small Driskell style fixture with index wheels about 8” in diameter. It seems OK up to about 24 segments but over that, I don’t feel the spacing is accurate enough (index plate needs to be larger I’m thinking).

I also, have Seg-Easy open segments plates and they work well, but only go up to 48 segments, (they too have their inherent problems).

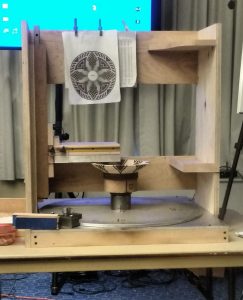

At the Symposium in Boston back in October 2016, I saw Ray Feltz’s fixture:

And Tom Lohman’s fixture:

They both have larger diameter index wheels, which makes all the sense in the world to me.

In order for me to increase my segment count and still be accurate, I decided to design and build my own open segment glue up fixture.

The one I built is similar to the fixture Tom Lohman uses, with my own twist on things.

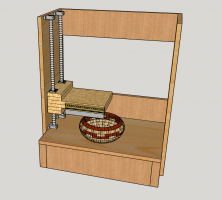

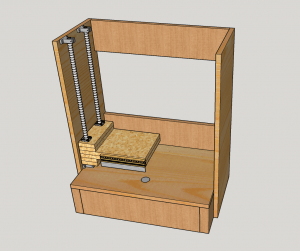

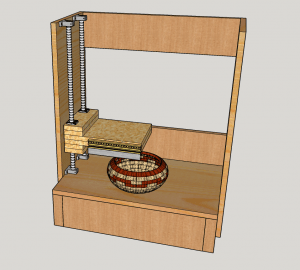

I started with a drawing in Sketch-up:

I made the materials list and picked up my materials. I had already picked up my bushings for the axle to hold the bowl. I just needed to get my timing gears, timing belt, stepper motor, and controller.

Oh, I forgot to say this baby is going to be computer operated.

I’ve been working with a member of AAW, Bill Ooms, who was developing a Rose Engine for ornamental turning on a wood lathe. He had developed an indexing software program in Java to run from a PC or a Mac but had abandoned this software for something different back in about 2011. He left it as open source software for anyone who could make use of it. I got a copy of his source code and worked on it for quite a while before I could get it back up and running on a newer computer. That’s when I really got going on this project. I did not want to start buying things and building stuff until I was sure the program was up and running.

If you would like to backtrack and follow my posts with Bill and see the help he gave me in updating the program you can find it here on the AAW forum.

The fixture is now looking like this:

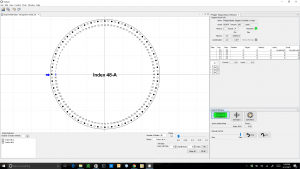

Here is a screenshot of the Indexing program.

The beauty of the computer indexing program is that I can have any indexing wheel I want. I just buy cheap xanax bars have to program it and that takes about two minutes.

I started building and now have something to work with:

This is it with the stepper motor attached:

Now I hooked it up to the computer to try it out:

Here is a short video of the first test run

Now I am ready to try my first project. I know there are going to be bugs and changes to come but the only way to find them is to try it and see what happens.

This is the first bowl in process with the new fixture.

60 segment per row

35 rows

2040 pieces

The first row is on:

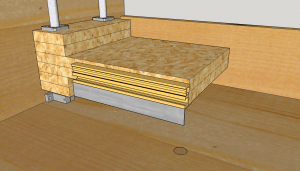

I got up to row 18 and was running into problems zeroing the index program with zero on the bowl, so I added a knife plate that slid into a notch cut into the side of the faceplate.

It worked good enough to finish the bowl but needed improvement if I want to go higher in my segment count.

This is the first finished bowl from the jig:

You can follow the above project as I build it on Woodturner PRO’s forums, Follow Along Projects, Here

Now that I am moving into a higher segment count and increasing to 96 segments per row, I’m going to add a flat plate between the faceplate and my waste block. By drilling a hole in this plate and a matching hole in the fixture, I will insert a pin in them to ensure that it will lock at the same zero point every time.

I am are off and running on making the new bowl.

Things are running well until I start getting up to around row 55 and then the little slop that there is between the bronze bushings and the axle starts showing it’s ugly head. I can reduce it by tightening down the locking nut, but then the stepper motor doesn’t have enough power to turn the spindle. So it is time to go to bearings. This is what I should have done in the first place, but I was trying to keep the price of the jig down.

This is it with the new bearings in place:

It is now rock solid and I can finish the bowl.

Again, you can follow the above project as I build it on Woodturner PRO’s forum, Follow Along Projects, Here

Anyone interested in the components or to get a copy of the indexing program or my Sketch-up drawings can contact me thru the forum and I would be happy to assist.

Bob Beaupre

Green Bay, WI